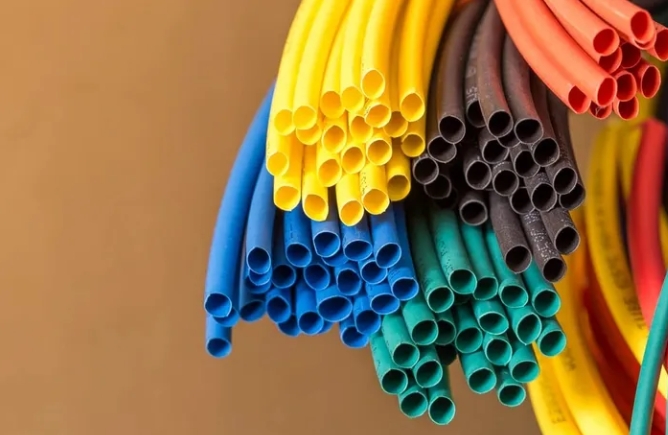

Expansion of heat shrink tube - single wall tube and double wall tube

Single-wall tubes are candidates for insulation, stress relief, wear protection, and mechanical strain. A common and widely used single wall tube is the G5 universal heat shrink tube. It is a UL VW-1 grade low shrinkage temperature polyolefin. (The contraction temperature considered "low" is in the 90°C range, not as hot as boiling water.) The characteristics of this tube family include a high degree of flame retardancy. Mechanical properties such as flexibility and 2:1 shrinkage ratio make it a candidate for general insulation of series electrical components. For example, it is common to find insulated wire connectors or rear insulation used as non-insulated terminals or connectors.

Other more professional single wall heat shrink tubes are also available. An example is FEP200℃ heat shrink bushing, which has high wear resistance and solvent resistance. The other is the HTK150PVDF heat shrink sleeve, which is made of semi-rigid polyvinylidene fluoride. It's designed to handle the heat. Its shrinkage temperature is in the same range as its operating temperature of 175°C. It is a candidate for demanding applications involving the protection of precision electronic components.

The PFA heat shrink bushings are translucent, so it simplifies inspection of the protected components. Another heat shrink tube for harsh environments is the DR-150℃ oil resistant heat shrink tube, a flexible, chemically resistant elastic tube. It is particularly suitable for military ground vehicles as well as off-road equipment and racing cars, as it performs well in high temperatures and in the presence of moisture and liquids.

There are a variety of other options for single-wall tubes. Some types have bright colors or have a shiny look that blends in with consumer electronics. Others have high shrinkage to accommodate irregular shapes. Some can even print logo text. In addition, single-wall tubes can also be considered for decorative applications or other uses unrelated to electronics. Hand tool manufacturers sometimes shrink the tubes around the handles of their products for ergonomic or wear protection.

Double-walled tube

The double-walled pipeperforms well in corrosion protection and sealing. It consists of an outer tube, much like a single wall, and the inner layer is usually composed of a sealant or adhesive. Sealants protect connections and components from splash and corrosion. Adhesives go a step further and help seal the tube to plastic, metal, rubber or other substrates. Applying heat to this specialized tube will shrink the outer layer, while the inside will melt and flow to protect against environmental factors.

In addition to their sealing properties, double-walled tubes typically have a higher shrinkage rate. Therefore, it tends to be used for maintenance as well as protection of equipment. For example, ATM is a mid-wall heat shrink tube commonly used in cable joint protection and metal pipe corrosion protection, and the polyolefin outer layer and the inner thick layer of hot melt adhesive can provide long-term and reliable protection for items in the outdoor environment.

Deal with special problems

Heat shrinkable profiles can be formed or extruded. This allows for special shapes and sizes of insulation. To make such a part, the substrate is first molded, then cross-linked and finally expanded. A typical application of molded shapes is as a sheath for sealing the back of connectors and sensors. Molded shapes are typically characterized by features with multiple openings, different angles, or both. However, molded shapes tend to be more expensive than extruded tubes. The cost of tubing length is usually measured in cents; The cost of molding shapes goes into the dollar range. Some common molded shapes include transition pieces, tap pieces, boots, LIDS, and connector back shells for circles and D-type subminiature.

There are also heat shrink fabrics. They are designed primarily to prevent wear and tear, not just to act as insulators. They are commonly used in parts such as rubber hoses, plastic pipes and wiring harnesses. The fabric combines heat shrinkable polyolefin threads in the circumference and non-shrinkable polyester threads in the longitudinal direction, which are woven together. Such as BSPET braided expansion tube.