Working on a tough new project? The kind that needs top-notch high-frequency shielding, serious heat resistance, and has to meet mil-spec standards? When I see an inquiry asking for AA59569 and ASTM-B298 right out of the gate, I know we're speaking the same language.

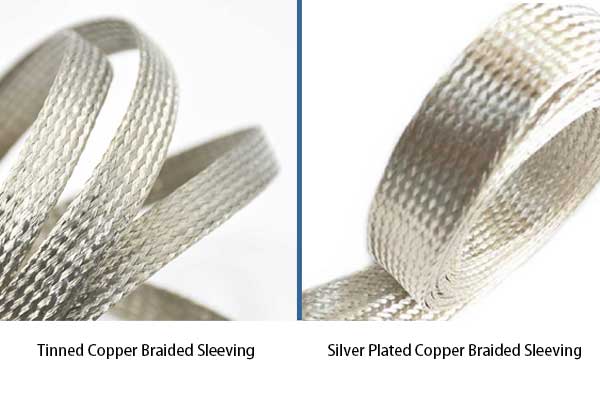

In these scenarios, standard tinned copper braid is like trying to survive an Arctic winter in a t-shirt—it might work for a second, but you're gonna have a bad time. So why is silver-plated copper the undisputed "only choice" here? Let me break it down for you.

1. Who Can Actually Handle the Heat?

You know tin has a low melting point (around 230°C/446°F). In environments consistently above 150°C, that tin plating starts to soften, get brittle, can even melt, and it oxidizes like crazy. The result? Shielding effectiveness tanks and ground resistance skyrockets.

Silver plating? It laughs in the face of continuous 200-250°C and can handle short-term peaks up to 300°C. It's like putting a firefighter's suit on your cable. It guarantees your shielding and grounding will be rock-solid, even when things get hot under the hood. That "exceeding 150°C" line in your spec is the most important dividing line.

2. The "Express Lane" for High-Frequency Signals

Modern equipment runs at higher and higher frequencies, and electricity loves to travel on the surface of the conductor (the "skin effect"). This is where silver, the "king of conductivity," absolutely dominates. It provides the lowest-impedance express lane for high-frequency signals, minimizing loss and maximizing shielding. Tin's conductivity, in comparison, is a bumpy dirt road. If you're working on high-frequency apps, precision medical gear, or military comms, you gotta choose the best road.

3. It's Expensive, But For a Good Reason

Let's not beat around the bush. Silver-plated copper costs significantly more. That's a fact.

But we engineers have to think beyond the BOM cost. You have to calculate the Total Cost of Ownership (TCO). For a critical system, a single failure caused by inadequate shielding—leading to downtime, field service, or a product recall—would cost more than you'd ever save on the cheaper braid. You're making a smart investment: higher initial cost for dramatically lower risk and maintenance costs over the life of the product. Its superior corrosion and oxidation resistance is the secret to long-term reliability.

So, if your project requires:

Handling sustained high temperatures (>150°C)

Guaranteed elite high-frequency shielding (EMI/RFI)

Compliance with harsh mil-spec (A-A-59569), aerospace, or medical standards

The ultimate in long-term reliability

There's only one answer: qualified silver-plated copper braid. It's not an "upgrade option"; it's the "entry ticket" to meet basic performance requirements.