As industries accelerate toward electrification and cleaner technologies, the demand for dependable electrical insulation is reaching new heights. From electric vehicles to renewable energy infrastructure, high-temperature environments are now the norm—not the exception. In this context, enhanced fiberglass sleeving has emerged as a critical solution for cable protection in demanding applications.

Why High-Temperature Cable Protection Matters More Than Ever

As industries pivot toward electric mobility, green energy, and smart manufacturing, the electrical systems that power these technologies are facing increasingly harsh conditions. Cables in EV battery packs, solar inverters, wind turbines, and automated machinery must withstand extreme temperatures, mechanical stress, and potential fire risks.

Recent events like battery fires, factory overheating, and weather-related failures have exposed the risks cables face in high-temperature conditions. These challenges underscore the importance of reliable cable insulation that can endure such stress without compromising safety or performance.

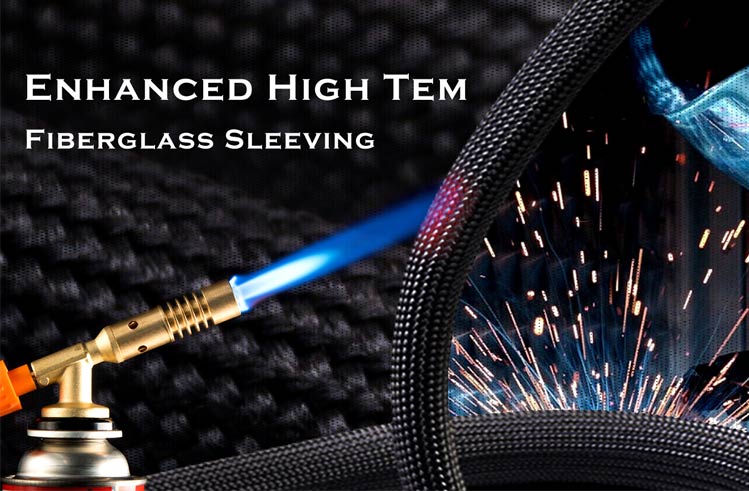

What is Enhanced Fiberglass Sleeving?

Enhanced fiberglass sleeving is a flexible, braided thermal insulation sleeve made from woven fiberglass yarn, often coated with materials like silicone, acrylic, or polyurethane to enhance heat resistance and durability. Standard versions can typically withstand temperatures up to 550°C (1022°F), while enhanced variants may handle even higher limits depending on the coating.

Key advantages include:

✅ Flame Retardancy: Prevents ignition and reduces fire spread

✅ High Thermal Endurance: Ideal for continuous exposure to heat

✅ Abrasion and Chemical Resistance: Ensures long-term protection in harsh conditions

✅ Electrical Insulation: Adds another layer of protection for power and control cables

Applications in a Greener, Electrified Future

1. Electric Vehicles (EVs):

As EV production surges, battery safety is a key concern. Enhanced fiberglass sleeving is used to shield high-voltage wires and prevent short circuits or thermal runaway events.

2. Renewable Energy:

In solar power systems and wind turbines, components are often exposed to high temperatures and UV radiation. Fiberglass sleeving helps protect inverter wiring and control units.

3. Smart Factories & Automation:

With the rise of Industry 4.0, machines run 24/7 in high-speed, high-heat environments. Enhanced sleeving helps extend cable life and reduce downtime in such settings.

4. Aerospace & Defense:

High-stakes sectors require flame-resistant materials that can handle rapid temperature changes and extreme conditions—making fiberglass sleeving a preferred choice.

Why Now?

Global events, such as supply chain disruptions and energy shortages, are driving industries to invest in more resilient infrastructure. At the same time, government regulations—such as fire safety standards in Europe and UL/CSA certifications in North America—are tightening.

Enhanced fiberglass sleeving meets or exceeds these standards, making it a proactive choice for manufacturers and engineers who prioritize compliance, safety, and long-term reliability.

As the world transitions toward smarter, greener, and more electrified systems, choosing the right cable protection is not just an engineering decision—it’s a strategic one. Enhanced fiberglass sleeving offers a future-proof, cost-effective, and safety-driven solution for high-temperature environments across sectors.

Whether you are designing the next electric vehicle platform, upgrading industrial equipment, or building tomorrow’s energy grid, investing in superior cable insulation like enhanced fiberglass sleeving is a step toward greater safety, sustainability, and performance.