In fast-moving industrial environments, cables face constant stress from movement, friction, and exposure to heat or chemicals. Over time, this can lead to insulation wear, signal interference, or even complete failure — causing production delays and increased maintenance costs.

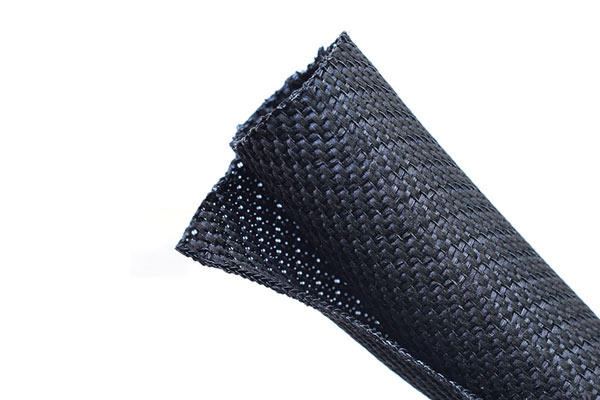

To address these challenges, MJ provides self-rolling textile sleeves, a practical solution designed to protect and manage cables in automation systems. These sleeves combine flexibility, durability, and ease of installation, making them suitable for a wide range of applications.

Key Advantages of MJ Self-Rolling Textile Sleeves

1.Quick and Tool-Free Installation

The self-rolling, open design allows the sleeve to wrap around cables without dismantling existing harnesses, saving time during assembly, upgrades, or maintenance.

2.Durable Material for Harsh Environments

Constructed from high-strength polyester, these sleeves withstand temperatures from –50°C to +150°C. They are abrasion-resistant, flame-retardant (UL94 V0 optional), and maintain performance even under industrial conditions.3.Flexible and Expandable

Available in sizes from 10mm to 50mm, these sleeves can accommodate varying cable diameters, simplifying inventory and reducing the need for multiple product variants.4.Organized, Safe, and Professional

By keeping wires neatly bundled and separated, the sleeves enhance safety, reduce tangling, and create a visually clean layout, improving both operational efficiency and aesthetics.

Typical Applications

Automated production lines: Protect signal and power cables in robot arms and conveyor systems.

Control panels and switchgear: Maintain organized and safe wiring.

Cable drag chains and moving machinery: Ensure long-lasting protection for cables subjected to motion and abrasion.

With MJ's Self-Rolling Textile Sleeves, industrial automation projects gain a reliable, long-term cable management solution that reduces downtime, protects valuable components, and improves overall productivity.