When choosing braided cable sleeves for electrical, automotive, or industrial use, it’s not just about flexibility or abrasion resistance. One of the most important performance factors is how the material behaves under fire. That's where flammability testing becomes essential.

Flame Testing for Braided Cable Sleeves – What to Look For

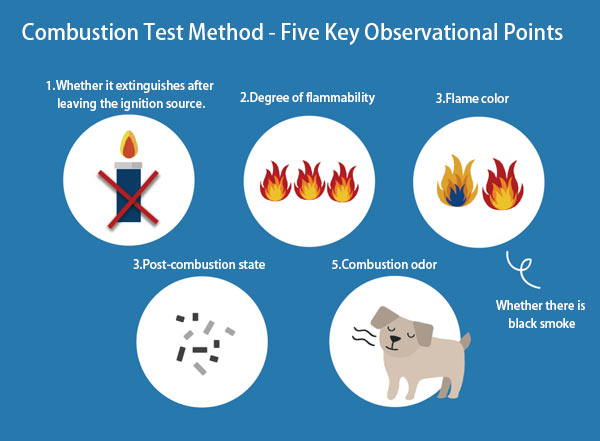

Here are five critical aspects you should observe when performing a flame test on materials used for braided cable sleeves:

Self-Extinguishing Behavior

Does the sleeve continue to burn after the flame source is removed?

Self-extinguishing sleeves are essential for enclosed environments like control panels or automotive cabins.

Ignition Level

How easily does the material catch fire?

Some polymers ignite quickly and are unsuitable for high-risk installations.

Flame Color

What color is the flame—blue, orange, yellow, or sooty black?

The flame color can indicate the chemical makeup and potential toxicity of the material.

Residue and Dripping

What’s left after burning—does it melt, char, or drip?

Non-dripping, carbonized residues are typical of high-grade PET or fiberglass sleeves.

Smoke and Odor

Is there black smoke? Is the odor pungent or chemically irritating?

Heavy smoke and odor may signal halogenated compounds, which could violate environmental standards like RoHS or REACH.

Why It Matters: Fire Performance in Braided Cable Sleeves

Braided cable sleeves are widely used to protect wires and cables in:

Automotive wiring harnesses

Aerospace systems

Electrical cabinets

Robotics and automation equipment

While these sleeves offer excellent abrasion protection and bundle organization, their fire resistance can determine whether they are safe for long-term use.

That’s why most OEMs and system integrators require materials to comply with standards like:

UL 94 V0 – For flame retardancy in plastics

FMVSS 302 – For automotive interior materials

EN 45545-2 – For railway applications (Europe)

How to Perform a Simple In-House Flame Test (For Reference Only)

Always perform tests in a controlled, ventilated area with proper safety precautions.

Step-by-step:

Cut a small sample of the braided sleeve (~10cm)

Suspend the sample vertically using clamps

Apply flame for 10 seconds

Observe if it self-extinguishes once removed

Record flame color, smell, smoke, and post-burn residue

Note: This method does not replace official certification tests, but it helps identify unsafe or low-grade products.

Don't Skip the Flame Test

With increasing demand for safe, environmentally friendly braided cable sleeves, flame testing provides a fast and visual way to verify material performance. It allows buyers and engineers to:

Avoid substandard or counterfeit products

Validate supplier claims about flame retardancy

Ensure the material won’t endanger installations or violate regulations