The more delicate parts on the excavator are the hydraulic pipes, and a set of original hydraulic pipes is expensive. To extend the service life of the hydraulic pipe, in addition to the regular operation of the driver, proper maintenance methods, to a certain extent, also affect the life of the hydraulic pipe.

1、Be sure to wear a protective cover

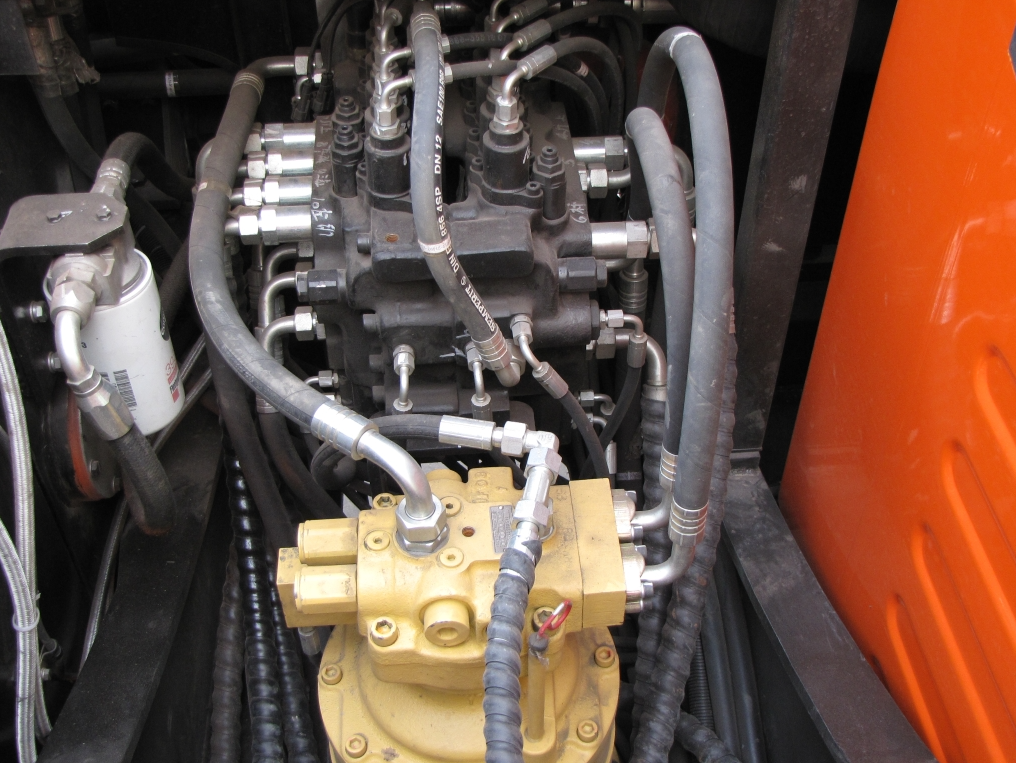

Gear pumps and piston pumps work with oil pulsation, this pulsation will make the hydraulic tube produce high-frequency vibration, and high-frequency vibration can not be completely eliminated.

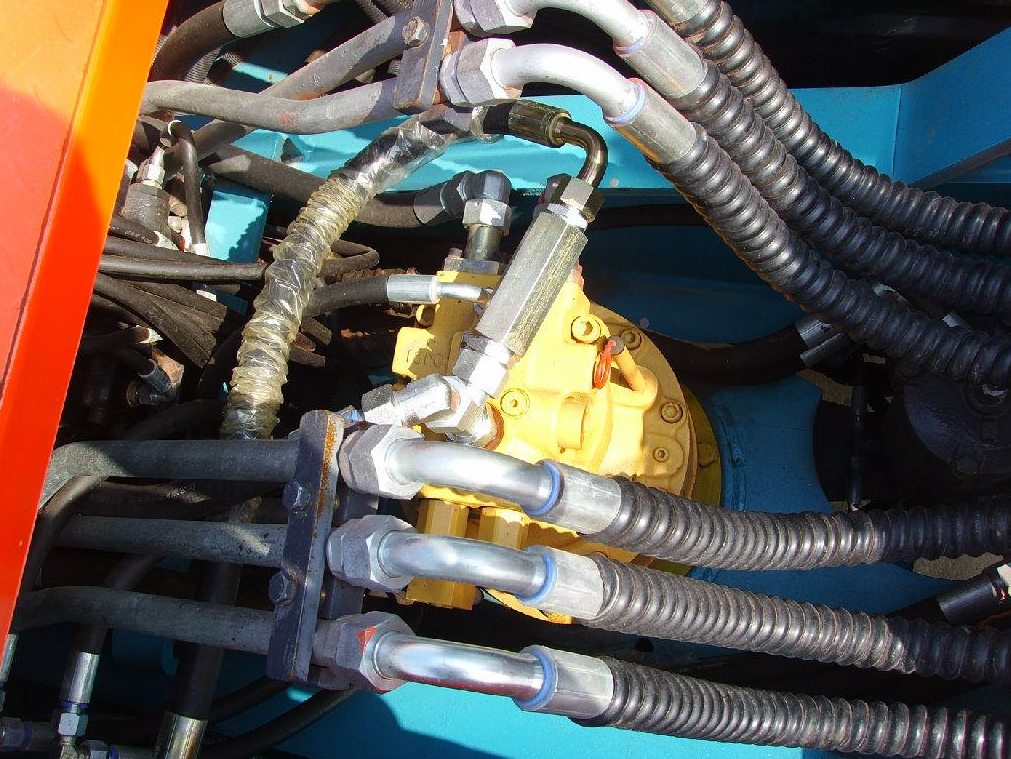

So the hydraulic tube has a special protective ring outside the set, the big arm root of the tube (plastic sleeve) and the small arm head of the tube (steel wire sleeve), this hose protective sleeve has a great role .

2, do not rub

Some excavator hydraulic pipe is later to match their own, the length is not quite appropriate and easy to interfere with the size of the arm friction or folding dead bend.

Friction will wear the outer wall of the hydraulic pipe caused by local thinning of the outer wall in the role of high pressure is easy to occur under the strong burst pipe phenomenon. Hydraulic tube folded dead bend will cause the local pressure increase, local temperature rise easily triggered by the hydraulic tube explosion.

3, do not touch the diesel and gasoline

Try not to let the hydraulic pipe contact with diesel and gasoline, although the hydraulic pipe is oil-resistant. But diesel and gasoline or a certain degree of aggressiveness, general rubber long-term immersion in diesel fuel will swell gel fluff.

4、The interface should be greased

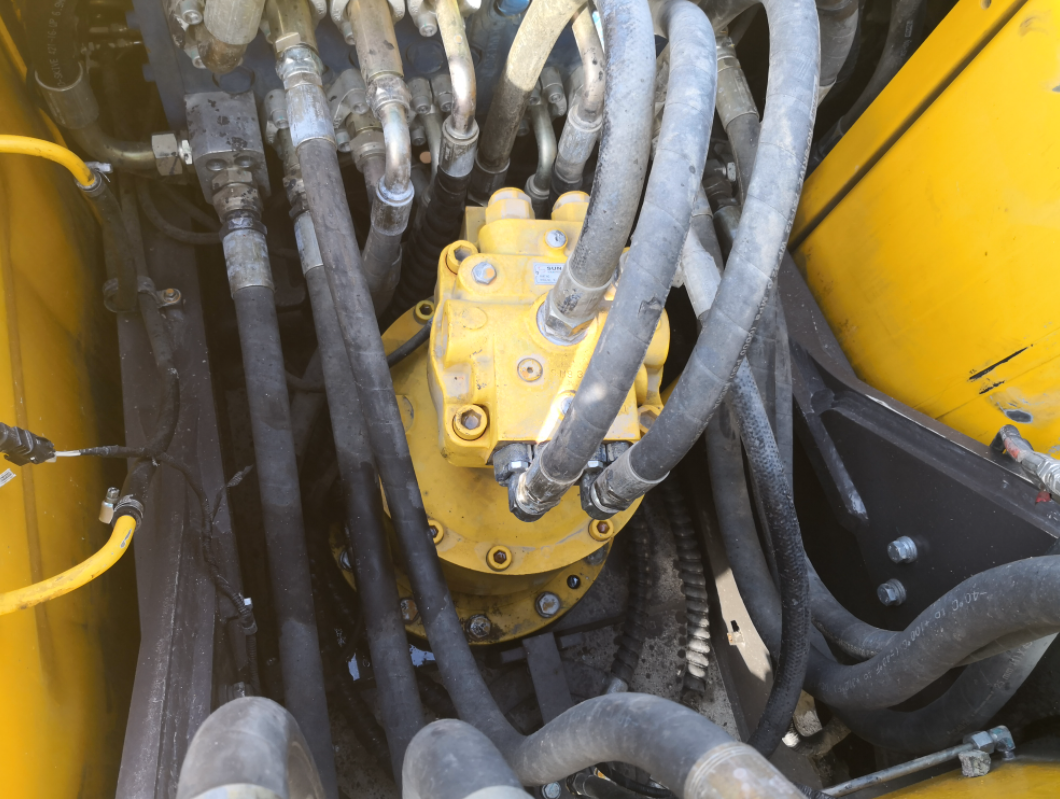

The center oil distributor and walking motor cover must be cleaned regularly, cleaned up after the butter smear into a protective layer, the buckle tube should also be smeared, try to avoid rust and corrosion in these places. Especially in coastal areas are often exposed to sea breeze and seawater, the buckle tube at the corrosion is easy to occur.

5、Installation should be in place

To the excavator on the installation of the pipe must be confirmed on the tight, not on the tight late loose oil seepage is a small matter, if the vibration wear interface plane on the trouble.