As the world accelerates toward electric vehicles (EVs), the demand for reliable, high-performance components has never been greater. One critical yet often overlooked element? Cable protection.

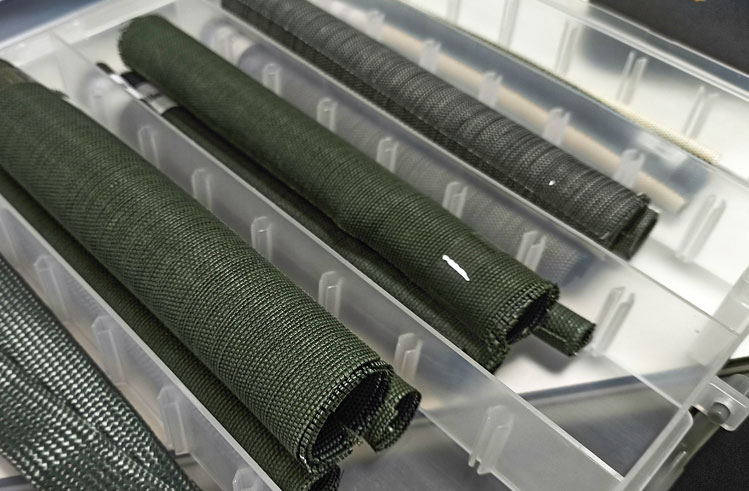

we specialize in braided sleeves engineered for extreme conditions—particularly the OHNS series, designed to safeguard high-voltage wiring in EVs, charging stations, and renewable energy systems.

Why Heat Resistance is Non-Negotiable in EV Cabling

EV batteries and power systems generate intense heat, with temperatures often exceeding 100°C in high-load conditions. Standard PVC or nylon sleeves degrade under such stress, leading to:

Insulation breakdown (fire risk)

Abrasion-induced failures (vibration from road conditions)

Premature aging (UV/solar exposure in outdoor charging stations)

Our PEEK monofilament (0.1–0.5mm) and aramid multifilament (200–8000D) sleeves solve these challenges with:

✔ Continuous operation up to 250°C (far beyond industry norms)

✔ 45%+ tensile strength retention after extreme UV/heat cycling (tested per ISO standards)

✔ 100+ steel needle abrasion cycles—critical for engine bay wiring

A European automaker previously faced warranty claims due to cracked cable sheathing in their battery packs. After switching to our texitile Textile sleeves, they saw:

Zero heat-related failures in 18 months of real-world testing

15% weight reduction vs. traditional metal conduit

Faster assembly (pre-slit design cut installation time by 30%)

Beyond EVs: Where Else High-Temp Sleeves Matter

Solar Farms – Withstands desert UV/heat while resisting sand abrasion

Aerospace – Protects avionics wiring from thermal cycling (-60°C to 200°C)

Industrial Robotics – Prevents downtime in high-motion cable carriers

Engineered for Supply Chain Certainty

We guarantee:

✅ Same-day sampling for urgent prototyping

✅ 30% faster lead times vs. imported alternatives (localized Asia/EU stock)

✅ Full test reports (including third-party validations)