Menu

- Home

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

- Products

- Braided Sleeving

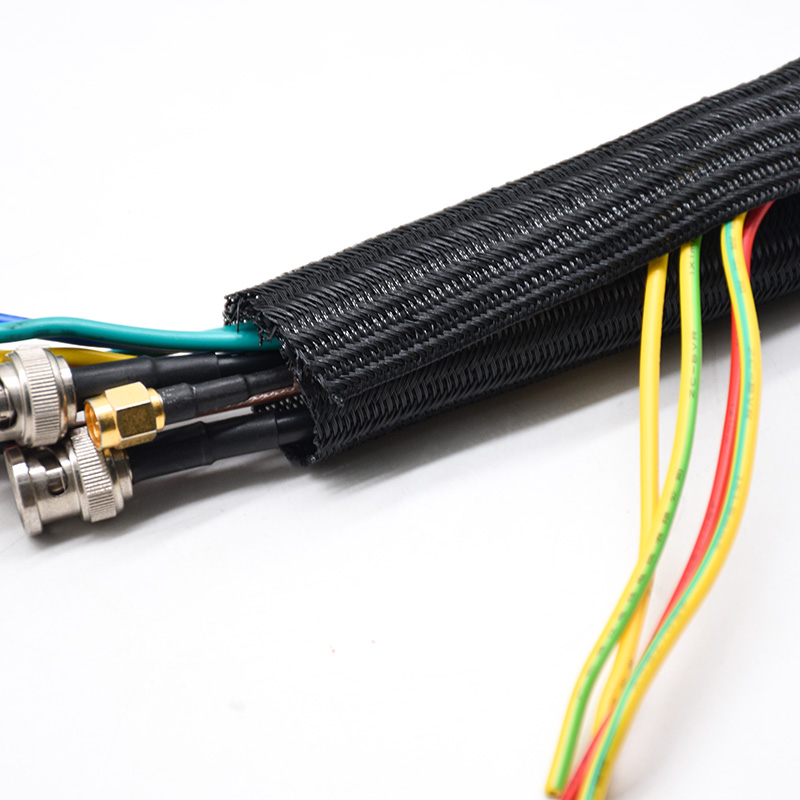

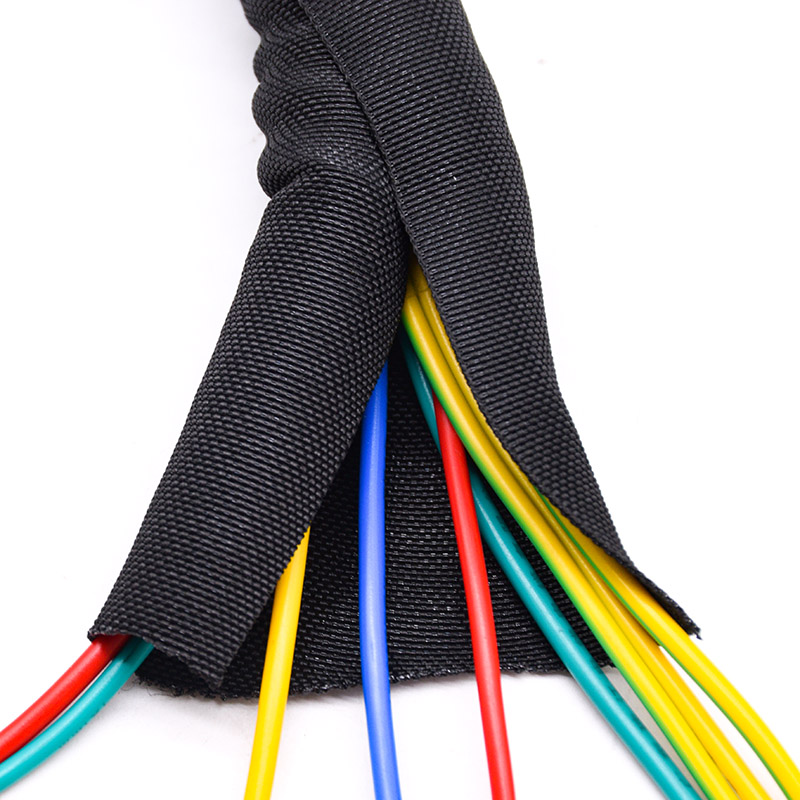

- Split Braided Wire Loom

- Wire Shielding Sleeve

- Hose Sleeving

- Heat Shrink Tube

- Fiberglass Sleeve

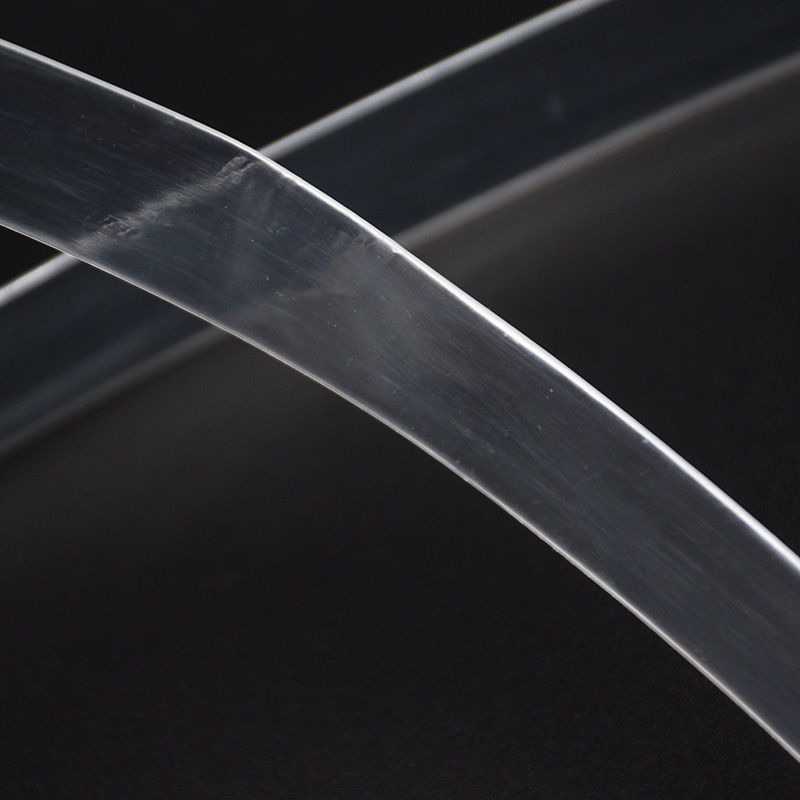

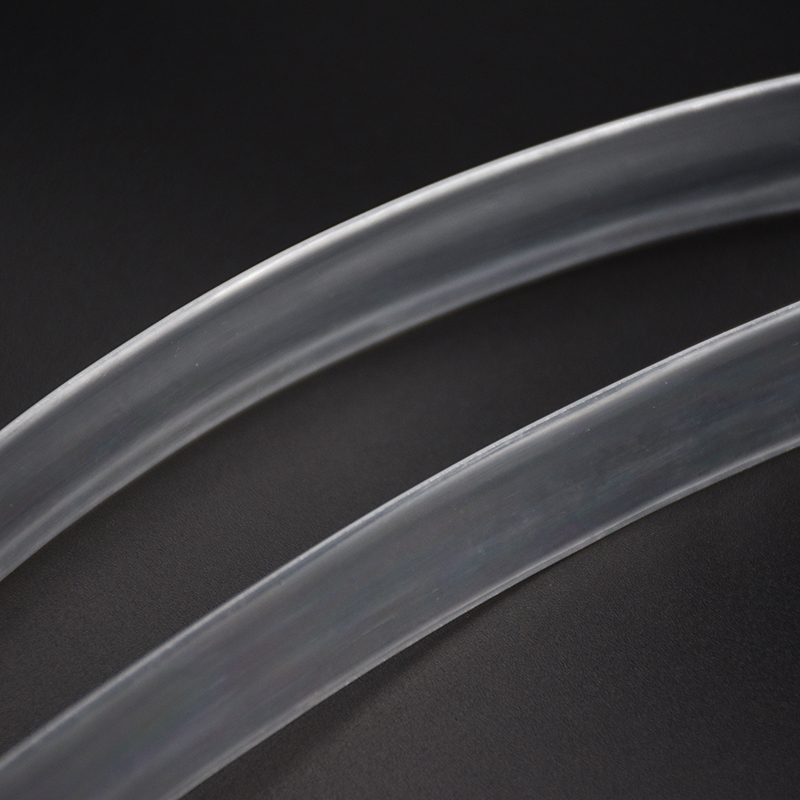

- Wire Loom Tubing

- Spiral Cable Wrap

- PTFE Cable Sleeve

- New Energy Cable Sleeve

- TERMINAL BLOCK

- Cable Gland

- News

- Company News

- Industry News

- Case

- Factory Show

- Production Equipment

- Storage

- Sample Showcase

- Laboratory

- Contact Us

Search