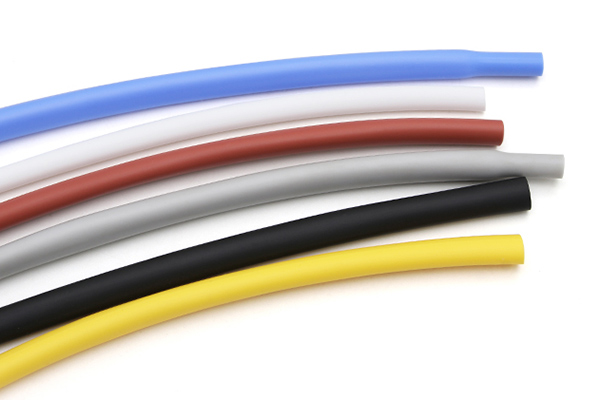

Heat shrink tubing is commonly used for insulating and protecting wires, cable sleeve, and other components.

The choice of material for heat shrink tubing depends on the specific requirements of the application.

Here are some common materials used for heat shrink tubing:

Polyolefin: Polyolefin is the most widely used material for heat shrink sleeve manufacturers.

It offers good electrical insulation, chemical resistance, and mechanical protection.

Polyolefin heat shrink tubing is versatile and suitable for a wide range of applications.

PVC (Polyvinyl Chloride): PVC heat shrink tubing is known for its flexibility, durability, and excellent electrical insulation properties.

It is resistant to chemicals, oils, and UV radiation.

PVC tubing is commonly used in electrical and automotive applications.

Fluoropolymer (e.g., PTFE): Fluoropolymer heat shrink tubing, such as PTFE (Polytetrafluoroethylene), offers exceptional resistance to high temperatures, chemicals, and fluids.

It has excellent electrical insulation properties and is often used in demanding industrial applications.

Silicone: Silicone heat shrink tubing has excellent flexibility and high-temperature resistance.

It can withstand extreme temperatures and has good electrical insulation properties.

Silicone tubing is commonly used in medical, aerospace, and automotive applications.

Dual-Wall: Dual-wall heat shrink tubing consists of an outer layer of polyolefin and an inner layer of adhesive or sealant.The adhesive lining provides environmental sealing and moisture protection.

Dual-wall tubing is often used in applications where moisture resistance is crucial, such as outdoor or underground installations.

When selecting heat shrink tubing, consider factors such as the operating temperature range, chemical resistance, electrical insulation requirements, flexibility, and the environment in which it will be used.

It's best to consult the manufacturer's specifications or seek expert advice to ensure the optimal material selection for your specific application.