When people think of braided sleeving, they usually associate it with cable management and wire harness protection.

But few realize that the structural advantages and material properties of braided sleeving make it equally valuable in water treatment, chemical dosing, and granular-media control systems.

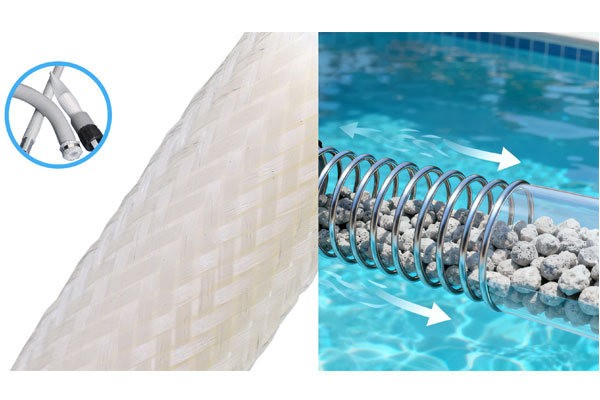

In many swimming pool circulation systems, lime granules or chlorine granules are commonly used as disinfectants.

Traditional solutions often rely on rigid filter cartridges or custom perforated tubes.

However, more and more engineers are choosing a lighter, more flexible, and more cost-effective alternative: large-diameter, expandable PET Tight Weave Braided Sleeving.

1. PET Material: Lightweight, Strong, Water-Resistant, and Chemically Durable

Tight weave braided sleeving is primarily made from PET (polyester).

Why is this material so widely used? Because it is incredibly durable:

High tensile strength – it won't deform when pulled or expanded

Excellent chemical resistance – stable even in alkaline environments created by lime or chlorine

Very low water absorption – won't swell or soften even after long-term immersion

High abrasion resistance – suitable for constant water flow and long-term soaking

In short, PET is one of the few textile materials that performs exceptionally well in prolonged underwater environments.

2. Tight Weave Design: Mesh Size Is Engineered—Not Left to Chance

The biggest advantage of Tight Weave Braided Sleeving is that its mesh openings are precisely engineered, not randomly formed.

Engineers can adjust:

Fiber diameter

Braid angle

Number of carriers on the braiding machine

Tension during braiding

to determine exactly how large or small each mesh opening will be.

Why does this matter?

Water can pass through freely

Granules stay inside without leaking

For disinfectant granules such as lime or chlorine, this is exactly what's needed:

Water goes in, dissolved solution flows out, particles stay contained.

To achieve this level of precision with plastic tubes, you would need molds, drilling, and machining—yet the accuracy still wouldn't match what braided structures can achieve.

3. Highly Expandable: Easily Fits Large Springs and High-Volume Granular Media

Plastic or metal tubes have almost no expansion capability.

Braided sleeving is different—it expands through structural geometry, not by stretching the material itself.

As the sleeve shortens, the diameter increases significantly.

This brings several benefits:

Easily fits large-diameter metal springs

Can expand to 100–150 mm

Can hold a large amount of granular media

Remains lightweight, flexible, and easy to install

A combination of high strength + expandability is rare in material design, making PET braided sleeving uniquely suitable for this application.

4. Stable Under Water Pressure: No Collapse, No Flattening, No Deformation

In swimming pool circulation systems, water pressure and flow direction often change.

Standard mesh fabrics may collapse or fold under these conditions, but tight weave braided sleeving holds its shape because:

The braided structure distributes load evenly

PET has natural flexural memory—compression won’t permanently deform it

An internal metal spring provides strong structural support

So even though it looks like fabric, it behaves more like a flexible, elastic shell that bends and adapts without collapsing or creasing.

5. Sleeving + Metal Spring: True Material Synergy, Not Just a Simple Combination

The effectiveness of this structure is not just because "a sleeve is placed over a spring."

The materials complement each other extremely well:

PET and stainless steel do not corrode each other

No galvanic reaction

Fibers won't be damaged by metal friction

Stable friction prevents the sleeve from slipping on the spring

This gives engineers confidence when designing expandable, large-capacity dissolving tubes for granular disinfectants.

6. Why Do Materials Scientists Appreciate This Design?

From a materials science perspective, this design simultaneously meets several engineering requirements:

| Engineering Requirement | How PET Tight Weave Braided Sleeving Solves It |

|---|---|

| Water permeability | Precisely controlled mesh structure |

| Chemical resistance | PET remains stable in alkaline environments |

| Flexibility | Textile-based structure fits various installation spaces |

| Large media capacity | Expanding geometry holds high media volume |

| No particle leakage | Mesh density can be customized to granule size |

| Low cost | No molds, no machining, lightweight construction |

Its true value lies not in complexity, but in the perfect harmony between material choice and braided structural geometry.